latest news:in the competitive state of an industry, the threat of substitutes is a decisive competitive force, and this kind of competition is easy to be ignored.

with the localization of adiponitrile, the by-products of adiponitrile, 2-methylpentanediamine and 1,2-cyclohexanediamine, as new amine curing agents that are also epoxy resin amine curing agents, will gradually mass production will gradually replace the current hot product polyetheramine.

polyetheramine (pea), also known as amino-terminated polyether and polyether polyamine, is a kind of polymer with polyether structure as the main chain and amine group as the terminal active functional group. electrostatic properties and anti-fatigue properties, polyetheramine is a good epoxy resin curing agent, which is widely used as one of the curing agents for wind power blades. in addition, polyetheramines are also used in nstream applications such as adhesives, oil and gas extraction, and textile printing and dyeing.

last year, the profit of domestic polyetheramine may exceed 20,000 yuan/ton, and the profit per ton of polyetheramine in 2022 will also exceed 10,000 yuan/ton.

announced that starting april 18, 2022, or as existing contracts allow, it will increase prices for select polyetheramines it sells in north america. this is the second time that has raised the price of polyetheramine products in 2022. on january 15, has made a substantial price increase, and the largest increase has exceeded 10,000 yuan/ton. it can be seen that polyetheramine in foreign markets the product’s popularity and urgency.

in 2016-2020, china’s polyetheramine sales increased from 42,000 tons to 101,000 tons. in 2025, china’s polyetheramine demand is expected to increase to 148,000 tons. this year, four or five companies will build or expand production.

2-methylpentanediamine: methylglutaronitrile is the main by-product of adiponitrile production.

the production process of butadiene hydrocyanation to produce adiponitrile is mainly divided into three parts: primary hydrocyanation, isomerization, and secondary hydrocyanation. the 3-pentenenitrile (3-pn), and hydrocyanic acid in the presence of a catalyst mainly generate adiponitrile and dimethylglutaronitrile (mgn). methylglutaronitrile can be hydrogenated to synthesize methylpentanediamine. the annual output of 300,000 tons of butadiene hydrocyanide adiponitrile production plant will produce more than 50,000 tons of 2-methylpentanediamine.

at the same time, 2-methylglutaronitrile is also a by-product of adipic acid-catalyzed ammoniation to produce adiponitrile.

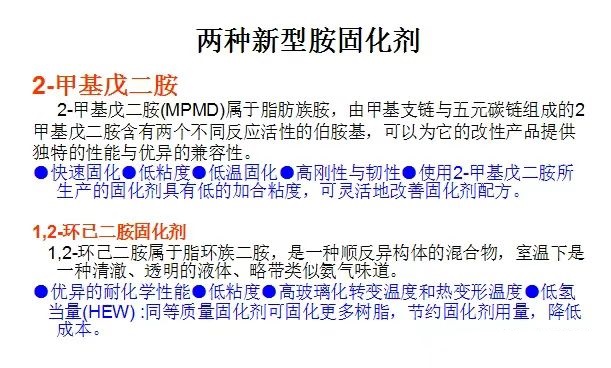

2-methylpentamethylenediamine (mpmd) is an aliphatic amine. the 2-methylpentamethylenediamine composed of a methyl branched chain and a five-membered carbon chain contains two primary amine groups with different reactivity, which can be used for its modification. products offer unique properties with excellent compatibility. curing agents produced using 2-methylpentamethylenediamine have low adduct viscosity, allowing flexibility to improve curing agent formulations.

1,2-cyclohexanediamine: the by-product 1,2-cyclohexanediamine is produced during the hydrogenation of adiponitrile to produce hexanediamine.

1,2-cyclohexanediamine is a cycloaliphatic diamine, which is a mixture of cis and trans isomers. it is a clear, transparent liquid at room temperature with a slight smell similar to ammonia. the same quality curing agent can cure more resin, saving the amount of curing agent and reducing the cost.

in addition, hexamethylene diamine can also be used as a new type of amine curing agent after modification, and a new type of epoxy resin curing agent is synthesized with thiourea modified m-phenylenediamine and hexylene diamine.

hexamethylenediamine produced by hydrogenation of adiponitrile can also be used as amine curing agent:

thiourea modified m-phenylenediamine and hexamethylene diamine epoxy curing agent, flexible curing agent containing methylene segment and some new amine curing agents.

it should be pointed out that the understanding of substitutes should not be limited to “different manifestations of functionally similar commodities”, such as 2-methylpentanediamine, 1,2-cyclohexanediamine, thiourea-modified m-phenylenediamine and some new amine curing agents such as diamine epoxy curing agent may not be a direct competitive substitute for polyetheramine, but the total market consumption of epoxy curing agents, because all products compete for market share, while the dosage of users is fixed and limited. the dosage of 2-methylpentanediamine and 1,2-cyclohexanediamine is a little more, and the dosage of polyetheramine will naturally be less.

therefore, the substitute market cannot only be considered from the functional point of the product. in fact, the allocation of users’ consumption has become the basis for another level of substitute generation. insufficient awareness of alternatives can easily lead to underestimation of the threat or value of alternatives.